CENTENNIAL, Colo. (August 7, 2019) – NioCorp Developments Ltd. (“NioCorp” or the “Company”) (TSX: NB; OTCQX: NIOBF) is pleased to announce the successful production of an Aluminum-Scandium (“AlSc”) master alloy using a metallurgical process that helps to prove out a commercial pathway to potential production of the master alloy.

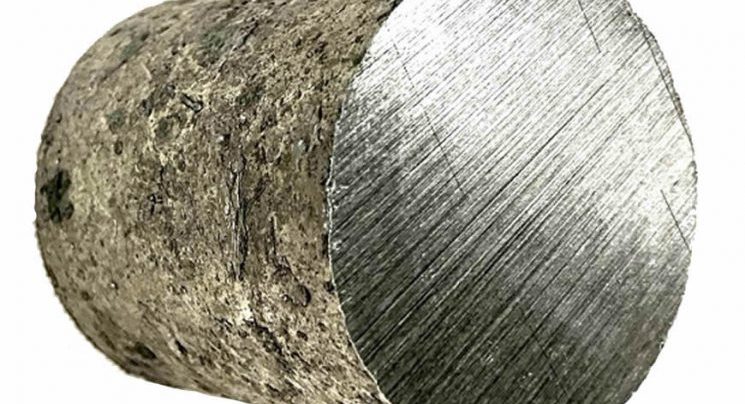

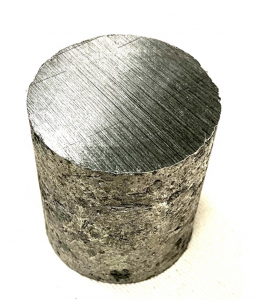

NioCorp’s Aluminum-Scandium master alloy being produced in Ames Laboratory’s high-temperature induction furnace.

The AlSc master alloy was produced at Ames Laboratory’s Materials Preparation Center, located in Ames, Iowa, under the supervision of NioCorp engineers and employing an improved production methodology specified by Tactical Alloys, a firm with over 20 years of experience in the AlSc alloy space. Ames Laboratory is a U.S. Department of Energy national laboratory recognized as a world leader in the research and development of rare earth and rare metal materials, such as scandium. NioCorp commercially purchased the scandium used to create the master alloy at Ames Laboratory’s Materials Preparation Center.

AlSc master alloys are used to introduce scandium into final casting-type and wrought-type aluminum-based alloy melts. Even a small amount of scandium can provide multiple benefits to aluminum alloys, including grain refinement during casting and solidification; improved weldability for minimizing weld cracks and failures; and increased yield and tensile strength of the alloy, which in turn can reduce the mass (weight) of platforms such as aerospace systems, cars, trucks, and buses, thus increasing fuel economy and reducing air emissions.

The recent alloy production was the second such AlSc master alloy production test run performed by NioCorp and researchers at Ames Laboratory’s Materials Preparation Center. NioCorp is currently developing its proposed Elk Creek Superalloy Materials Facility in southeast Nebraska, which is expected to produce approximately 95 tonnes of Scandium Trioxide annually once it is constructed and enters commercial operation, according to the Company’s April 2019 Elk Creek Project Feasibility Study. Current global production and consumption of scandium is estimated by the U.S. Geological Service (“USGS”) to be approximately 10-15 tonnes per year, most of which is believed to be produced in China.

When NioCorp’s Elk Creek mine and processing facility are operational in Nebraska, it will establish the U.S. as a global leader in the production of the high-value rare earth element.

AlSc Master Alloy Produced By Ames Laboratory and NioCorp

In October 2018, NioCorp signed a commercial sales agreement with Traxys North America LLC for up to 120 tonnes of scandium trioxide over the first 10 years of operation of NioCorp’s Elk Creek Project. Traxys is obligated to purchase 12 tonnes per year of scandium trioxide for the first 10 years of the Project’s production, subject to satisfaction of certain conditions. That annual amount represents approximately 10 percent of NioCorp’s planned annual production of scandium. Traxys can purchase more than 12 tonnes per year from NioCorp, and the agreement can be extended beyond the 10-year term, by mutual agreement. The contract presupposes the Company securing project financing, obtaining all necessary approvals, and constructing a mine and processing facility at Elk Creek.

“We wish to thank once again the outstanding team at the Ames Laboratory, the U.S. Department of Energy, and our friends at Tactical Alloys for their assistance to our team in completing this second test production of Aluminum-Scandium master alloy,” said Mark A. Smith, CEO and Executive Chair of NioCorp. “This production run has helped to further refine what we believe is the likely metallurgical approach we would employ in making Aluminum-Scandium alloy for commercial markets. We very much look forward to the possibilities presented by the establishment of a domestic U.S. production capacity for Aluminum-Scandium master alloys that can utilize scandium sourced and purified in the U.S.”

Qualified Persons: Scott Honan, M.Sc., SME-RM, of NioCorp Developments Ltd., a Qualified Person as defined by National Instrument 43-101, has read and approved the technical information contained in this news release.

# # #

Source: NioCorp Developments, Ltd.

https://www.niocorp.com

@NioCorp $NB $NIOBF #Niobium #Scandium #ElkCreek #AmesLab #DOE #TacticalAlloys

For More Information:

Contact Jim Sims, VP of External Affairs, NioCorp Developments Ltd., 720-639-4650, [email protected]

About NioCorp

NioCorp is developing a superalloy materials project in Southeast Nebraska that will produce Niobium, Scandium, and Titanium. Niobium is used to produce superalloys as well as High Strength, Low Alloy (“HSLA”) steel, which is a lighter, stronger steel used in automotive, structural, and pipeline applications. Scandium is a superalloy material that can be combined with Aluminum to make alloys with increased strength and improved corrosion resistance. Scandium also is a critical component of advanced solid oxide fuel cells. Titanium is used in various superalloys and is a key component of pigments used in paper, paint and plastics and is also used for aerospace applications, armor and medical implants.

About Ames Laboratory

Ames Laboratory is a U.S. Department of Energy Office of Science national laboratory operated by Iowa State University. Ames Laboratory creates innovative materials, technologies and energy solutions. We use our expertise, unique capabilities and interdisciplinary collaborations to solve global problems.

About Tactical Alloys

Tactical Alloys applies alloy innovation tactics for sports equipment, firearms and military applications.

Cautionary Note Regarding Forward-Looking Statements

Certain statements contained in this document may constitute forward-looking statements, including but not limited to statements regarding NioCorp’s ability to produce scandium in sufficient quantities and quality to meet the requirements of Traxys and other customers, Traxys’ ability to sell NioCorp’s scandium products, and NioCorp’s plans to potentially produce and/or commercialize scandium-contained alloys. Readers are cautioned that such forward-looking statements involve known and unknown risks, uncertainties and other factors that may cause a change in such assumptions and the actual outcomes and estimates to be materially different from those estimated or anticipated future results, achievements or position expressed or implied by those forward-looking statements. Risks, uncertainties and other factors that could cause NioCorp’s plans or prospects to change include risks related to the Company’s ability to operate as a going concern; risks related to the Company’s requirement of significant additional capital; changes in demand for and price of commodities (such as fuel and electricity) and currencies; changes in economic valuations of the Project, such as Net Present Value calculations, changes or disruptions in the securities markets; legislative, political or economic developments; the need to obtain permits and comply with laws and regulations and other regulatory requirements; the possibility that actual results of work may differ from projections/expectations or may not realize the perceived potential of NioCorp’s projects; risks of accidents, equipment breakdowns and labor disputes or other unanticipated difficulties or interruptions; the possibility of cost overruns or unanticipated expenses in development programs; operating or technical difficulties in connection with exploration, mining or development activities; the speculative nature of mineral exploration and development, including the risks of diminishing quantities of grades of reserves and resources; and the risks involved in the exploration, development and mining business and the risks set forth in the Company’s filings with Canadian securities regulators at www.sedar.com and the SEC at www.sec.gov. NioCorp disclaims any intention or obligation to update or revise any forward-looking statements whether as a result of new information, future events or otherwise.